PROJECTS

Our company, with the experience, the knowledge, the specialized technical personnel and the modern technological equipment, undertakes the study of any system for the elevation of people or loads (according to the Community Directive 95/16 / EC and the international Standards EN 81-1, ΕΝ 81-2), always suggesting the appropriate transport system.

The study and design of each elevator is carried out by qualified personnel of the company (without any client financial obligations) who visit the site and gather every detail that will help in the best performance of the project. Once the study has been completed, the sales department undertakes the issue of the economic and technical offer which is delivered and presented to the client, through which the interested parties can obtain a complete view of the installation and operation of the elevator.

INSTALLATIONS

WITH ENGINE ROOM

Our company undertakes the installation of hydraulic elevators by proposing them as a simple and reliable solution for small or large loads up to 8 stops (up to 22 m) and speeds up to 0.80 m / s at relatively low cost.

WITHOUT ENGINE ROOM

Our company, in cases where there is no room for the engine room of the elevator in the building, installs ELEVER-HYDRO MRL, where the power unit and control panel are mounted in a specially crafted cabinet.

WITH ENGINE ROOM

Our company undertakes :

• The installation of mechanical elevators – as the most suitable – for multi-storey buildings, high traffic and increased load carrying needs, from 2 stops to 15 stops and at speeds from 0.60 m / s to 2.00 m / s.

• The installation of Inverter VVVF mechanical elevators for perfect operational results.

Our company installs FAER & TOPGEARS mechanical elevators.

WITHOUT ENGINE ROOM

Our company, in cases where there is no room for the engine room of the lift in the building, installs the ELEVER-TRACTION MRL with all its mechanical parts located in the well, and the control panel is placed in a suitable position next to the door usually on the top floor. In these cases, gearless gears are used, but machines with a gearbox are also excluded when the dimensions of the shaft allow it. Excellent motion quality and stop precision, using state-of-the-art materials. High energy efficiency using VVVF inverters. No restrictions on the number of floors of a building.

Our company undertakes the installation of cargo elevators with a payload of 500 kgr up to 16.000 kgr.

Cargo elevators may be hydraulic or electric to meet even the most demanding commercial or industrial needs.

Our company undertakes the installation of a food lifts.

They are small sized elevators ideal for lifting small items such as food trays.

Theis use is especially useful in restaurants, cafes, shops, offices, hotels. In many cases it is also placed in private homes. It is possible to fit into a special manhole from our company if there is no available shaft in the building for which it is intended.

Our company, aiming to serve people with disabilities represents the PROSPELASI special lift company and offers you products from European factories with a long history of stair lifts, such as Handicare, founded in 1886 and with the largest number of international sales. With the basic safety and reliability criteria, we have a wide range of products capable of being the definitive solution both in terms of functionality and aesthetics.

By studying each problem individually and according to its peculiarities, we have the ability to offer the best technical solution and support. Stair lifter systems are divided into two types in a seat and a wheelchair and are constructed for straight stairs and ladders, indoors or outdoors.

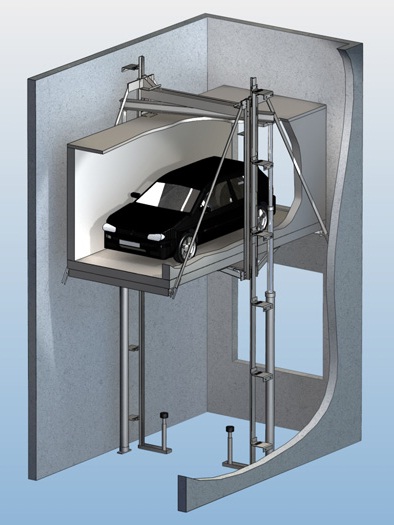

Our company undertakes the installation of various kinds of parking systems, ensuring the parking of two or four vehicles in a space intended for one or two, and the installation of a car lift for long journeys requiring vertical transport, from 2 to 12 meters, with a beneficial load 2.200kgr.

MAINTENANCE

Our company undertakes the maintenance of motor & amp; hydraulic elevators, guaranteeing the safe operation, on-time diagnosis and prevention of possible faults, as well as troubleshooting, thus increasing the life of both the parts and the actual elevator.

Maintenance is carried out by licensed, experienced and trained craftsmen at regular intervals and includes:

- Control of electrical and mechanical safety devices and other parts of the elevator.

- Adjustment of electrical and mechanical safety devices and other parts of the elevator.

- Lubricating the parts.

- Repairing emergency damage.

- Civil liability insurance in a private insurance company.

- Monitoring the smooth operation of the lift.

Our company, using an electronic database to record the maintenance program, damage, repairs and the complete history for each elevator, demonstrates the high quality of maintenance services that we provide.

REPAIRS – MODERNIZATION

Our company makes repairs to meet existing requirements, each material used for repair is manufactured to the highest safety standards. Repairs involve all the necessary actions that take place in the lift to replace an old or defective component with a new one.

According to the Laws: ΦΕΚ 2604/Β΄/22.12.2008 and ΦΕΚ 1797/Β΄/21.12.2005, all lifts are required to undergo periodic inspection and to comply with the European standard EN. 81.1 and EN. 81.2 for their certification.

The modernization of elevators for correct operation, safety, comfort and aesthetics may include :

- Replacing the elevator cabin.

- Replacing elevator doors.

- Replacement of the electrical installation of a shaft-engine room.

- Replacement of the chamber with built-in voice communication systems, security lighting, Display, overload, etc.

- Replacing elevatpr panels.

- Installation of automatic release.

- Installing Bus type interior cabin doors.

- Replacing locks with new interlocked locks (mechanical check of the closed position).

- Replacing a new electronic timer, with double independent relays, with a phase supervisor, etc.

- Replacing a function mechanism.

- Installing speed limiter so that it is independent from the single-way controller.

- Set up a control panel to offset the reactive power